Typically, the component remains stationary on the rotary table and the machines secondary spindle axis is employed to turn profiles & bores.

http://www.edgecam.com

Turning with Rotating Heads | Edgecam 2016 R2

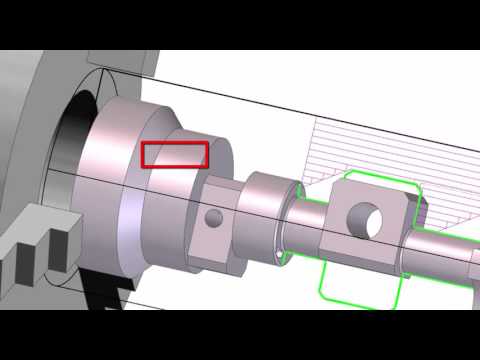

Popular in the Oil & Gas industry and, where large components are machined, Edgecam 2016 R2 now fully supports Rotary Heads on Milling machines (one example being Trevisan machine tools)

Typically, the component remains stationary on the rotary table and the machines secondary spindle axis is employed to turn profiles & bores.

http://www.edgecam.com

Rough Grooving | Edgecam 2016 R2

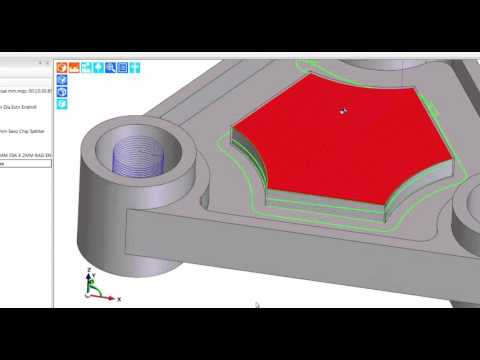

Rough Grooving has been in enhanced in Edgecam 2016 R2 whereby the cycle will now automatically remove excessive cuts when it detects a small radius or chamfer on a groove feature.

Moreover, the cycle now offers a new ‘Intermediate Cuts’ function for determining the number of extra passes required to machine across an overly large chamfer or radius on a groove feature.

http://www.edgecam.com

Nutated Head Table MTM | Edgecam 2016 R2

Edgecam 2016 R2 offers further support for multitask machine configurations by introducing support for Nutated Head on Mill Turn Machines.

This particular configuration is proving to be more popular throughout the industry where both Milling and Turning operations are combined. Fanuc; Siemens and Heidenhain controllers are supported in this configuration.

http://www.edgecam.com

EWS - 3D IGES import | Edgecam 2016 R2

Edgecam 2016 R2 continues to evolve its EWS product by supporting the import of 3D IGES wireframe files.

Once loaded the user deploys existing EWS tools (such as Sketch Plane and Ruled Surface) to convert the wireframe into a solid model.

http://www.edgecam.com

Multiple Wire EDM enhancements | Edgecam 2016 R2

As well as updating the Makino technology database and introducing new output options in the Machine Configurator, Edgecam 2016 R2 has enhanced its ‘Move’ command by adding Rotary angle control, and has added a brand new Translate function.

http://www.edgecam.com

File Tessellation Benchmark | Edgecam 2016 R2

Edgecam 2016 R2 offers significant time savings while loading solid model part files due to the introduction of tessellation. Benchmark trials produced an average file load 20 times faster.

Tessellation breaks the model down into triangles, which are then stored in such a way that they can be read back much faster than before.

http://www.edgecam.com

Editable Manual Turn feature | Edgecam 2016 R2

Edgecam 2016 R2 empowers a user to alter a Turned Profile Feature. Originally, having created the manual feature, it was not possible to extend or alter the profile. Simply checking the ‘Edit’ command now allows the user to influence the feature.

http://www.edgecam.com

Advanced 5-Axis Mirror | Edgecam 2016 R2

The ability to ‘Mirror’ a 5-Axis toolpath has been added to the Roughing tab. This not only creates a mirror image of a toolpath by reflecting it symmetrically but also alleviates the need to add extra transformation CAM instructions.

http://www.edgecam.com

Advanced 5-Axis Cycle | Edgecam 2016 R2

As well as the introduction of further ‘Collision check’ options, the ‘Multiblade machining’ module now offers a new strategy called fillet finishing. The new option allows users to quickly and easily finish machine filleted areas commonly found on impellor and blade components.

http://www.edgecam.com

Profiling Cycle and Dialog Pictures | Edgecam 2016 R2

Profiling cycle algorithm has been refined so as less code is generated but accuracy is maintained. This is clearly seen when a user picks solid edges or loops from a solid model. .

The ability to ‘Break Corner” is now supported when Compensation is set to Geometry.

Four extra CAM cycles have been upgraded so as they display pictures & context help on their dialogs.

http://www.edgecam.com

Profiling Cycle no roll over & Index command | Edgecam 2016 R2

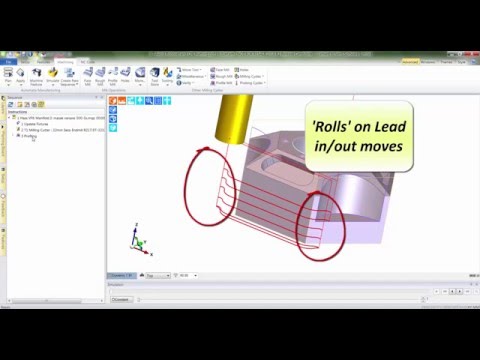

Further Profiling cycle improvements has resulted in the removal of ‘rollovers’ sometimes experienced when the cycle is set to “Pick Solid Faces”. The enhancement will be automatically applied when the toolpath is regenerated in Edgecam 2016 R2.

The ‘Index Move’ command has been enhanced with a new modifier - 'Define CPL Name'. In certain instances a User wishes to an exact CPL name as opposed to a ‘System’ name. This is especially beneficial when the code generator has been aligned to expect a specific name.

http://www.edgecam.com